Customer cases

Solumera contracting company works faster and more efficiently with the FlowBox for road salt

The challenge During the winter season, contractor Solumera frequently uses road salt, which is typically supplied in big bags. However, the volume of these big bags exceeds the capacity of...

Pre owned bigbag handling material

From time to time, we trade in used processing machines. These may be machines that still perfectly suit your needs. Curious about our stock? Send us a message!

Silo with bagging device for teff flour

We recently supplied a silo with a bagging system for a mill specializing in teff flour, allowing for the efficient filling of paper bags. The system is equipped with a...

Modulo HI stainless steel big bag unloading station for soft drink manufacturers

We recently delivered a Modulo HI-RVS to a soft drinks manufacturer in Central Germany. This customer will be using this discharge station to dispense sugar and various powders from big...

Modulo HI-DS for filling buckets from big bags

Our client, a supplier of compressed air systems for critical environments, was struggling to manually fill 10kg buckets with activated carbon and desiccant from big bags: the work was hard, dusty, and imprecise. By implementing three Modulo HI-DS® unloading stations, big bags could be unloaded dust-free and buckets filled accurately. This resulted in precision (0.1% deviation), a clean and ergonomic workspace, and cost savings through more efficient processing.

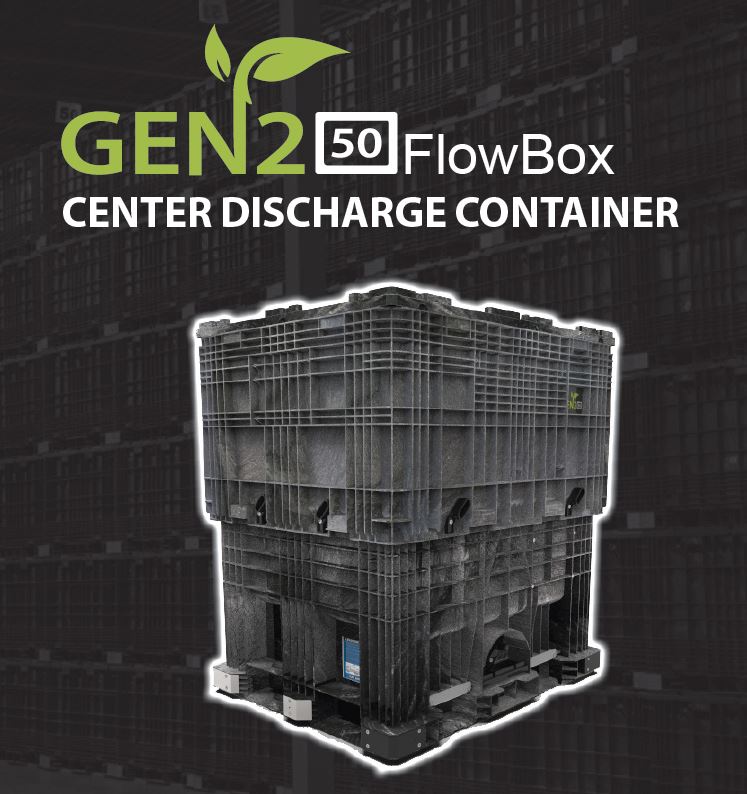

GEN250® FlowBox, the sustainable alternative for big bags. Be PPWR ready

The GEN250® FlowBox is designed for easier and more efficient processing of various raw materials. All rolling products that are transported in a big bag (FIBC) can also be transported...

Vidbag.nl wird auf der Solids Antwerpen vertreten sein

We will be present at the Solids trade fair in Antwerp and we would like to meet you there! you can find us at stand 4010E

Customer case "Peeze Coffee Roastery"

Peeze Coffee Roastery has been roasting and packaging coffee responsibly since 1879. The majority of the production goes in one line from the roaster and the bunkers in the desired...

MODULO SP WITH LARGE DOSING SLIDE

2 Modulos SP, with enlarged dosing slide, are on their way to Hungary. Thanks to this large slider, products that roll less well, such as cement, can still be unloaded...

BIGBAG LOGISTICS IN ORDER WITH THE NEVA SYSTEM

BigBag logistics in order with the Neva system – A perfect combination with Vidbag! We have recently become a dealer of Neva, a handy Big Bag Handling and storage...

Custom-made unloading stations for industrial bakeries in the USA

For a customer in the United States, we developed a customized version of our Modulo SP big bag unloading station. The standard dimensions didn't fit their existing workflow, requiring a custom solution.

We widened the legs to the customer's specific dimensions, lowered the discharge ramp to reduce dust formation, and added a tip-over protection for added safety.

Thanks to these adjustments, the customer can now dispense their big bags directly into the transport container, working more efficiently and saving time. The result: three fully customized unloading stations that perfectly match their process.